Ever walked into a garage or factory floor that looks like a patchwork quilt? Cracked spots here, sticky patches there—it’s the kind of mess that makes you cringe. I’ve seen it firsthand on job sites, where a quick fix turns into a headache that costs twice as much to redo. Epoxy floor coatings promise that tough, shiny surface everyone wants for workshops, garages, or warehouses. But get it wrong, and you’re staring at bubbles, peeling, or a floor that wears out faster than expected.

The good news? Most slip-ups are avoidable with a bit of know-how. In this post, we’ll walk through the top pitfalls folks run into when laying down epoxy floor coatings. We’ll keep it real—no fluff, just straight talk from years of watching projects go right (and wrong). Whether you’re a shop owner prepping a parking lot or a homeowner tackling the basement, these tips will save you time, cash, and frustration. Let’s dive in.

Why Epoxy Floor Coatings Rock for Tough Spaces

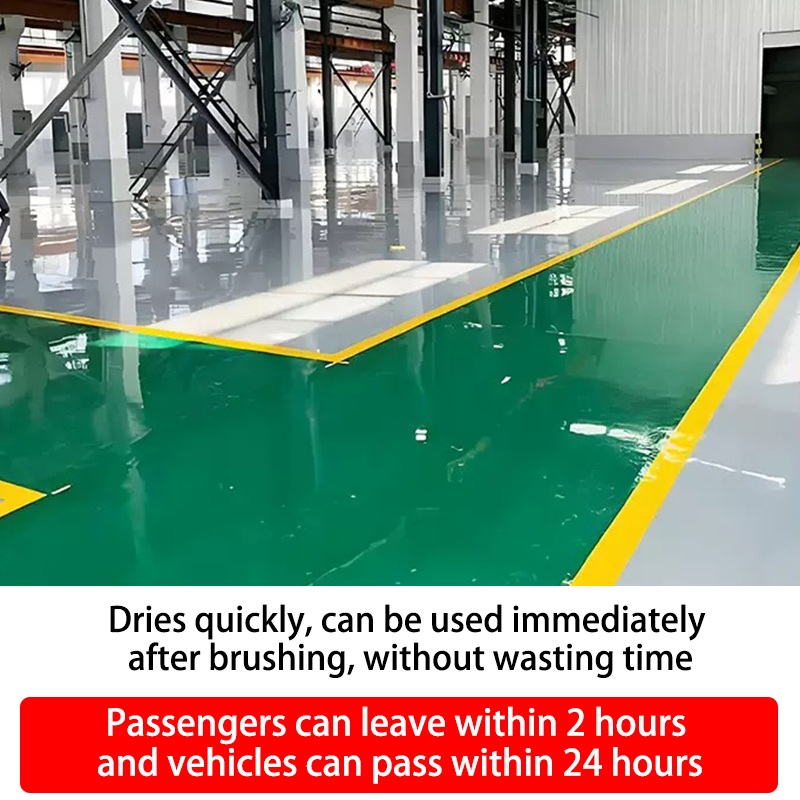

Before we hit the mistakes, a quick nod to what makes epoxy such a game-changer. These coatings aren’t your grandma’s paint job. They bond hard to concrete, shrug off spills like oil or chemicals, and hold up under heavy traffic. Picture a bustling warehouse where forklifts rumble all day—epoxy keeps the floor looking sharp without constant touch-ups.

From my experience on industrial sites, the best ones deliver high hardness to fight wear, resist oils and corrosives that eat away at plain concrete, and leave a glossy finish that brightens the whole space. They’re straightforward to apply, too, covering big areas fast. And the payoff? A surface that lasts years with barely any upkeep. Applications run the gamut: think grimy industrial workshops, exposed parking lots, stacked warehouses, damp basements, or sleek commercial floors. Done right, it’s like armor for your ground.

But yeah, even the toughest coating flops if you botch the basics. So, let’s unpack those common traps.

Mistake #1: Skipping Proper Surface Prep

Here’s where it all starts—or unravels. You roll up with your epoxy kit, eager to get that fresh coat down, but the floor’s a disaster: dust, grease, cracks, the works. I’ve lost count of how many times a crew calls it a day after bubbles pop up everywhere because they didn’t grind or clean first.

The Real Problem

Concrete’s porous, man. It soaks up oils and holds onto old paint like a grudge. If you slather epoxy over that mess, it won’t stick. Next thing you know, it’s peeling in sheets after a month of foot traffic. Data from coating pros shows up to 40% of failures trace back to lousy prep—yikes.

How to Dodge It

Grab a grinder or shot-blaster to etch the surface, exposing fresh pores for grip. Then hit it with a degreaser—something industrial-strength that cuts through years of grime. Rinse thoroughly, and let it dry completely. Pro tip: In a humid basement, run a fan overnight. It’ll save you from that sticky surprise.

Take a parking lot I helped with last summer. The crew etched the slab, vacuumed every speck, and the epoxy went on like a dream. Two years later? Still gleaming, no lifts from tire marks.

Mistake #2: Messing Up the Mix

Epoxy’s a two-part dance: resin and hardener. Get the ratio off—even by a splash—and you’re cooking up a soft, yellowing disaster. I remember a buddy’s garage project: he eyeballed it, and the floor turned tacky in spots. Stuck like glue to his shoes for weeks.

Why It Bites

The chemistry’s picky. Too much hardener, and it cures too fast, trapping air bubbles. Skimp on it, and the coating stays gummy, inviting dirt and wear. In high-traffic spots like logistics centers, that means cracks under load, leading to repairs that eat your budget.

Fix It Like a Pro

Follow the label to the gram—most kits call for a 2:1 resin-to-hardener mix. Use a scale if you’re paranoid (I do). Stir slow and steady for three minutes, scraping the sides. No rushing; let it sit a tick to de-gas. For bigger jobs, like a 5,000-square-foot warehouse, mix in batches to keep it fresh.

Oh, and a side note: Ever notice how some folks treat mixing like baking cookies? It’s not—skip the wooden spoon; go for a drill paddle to avoid lumps.

Mistake #3: Ignoring Weather and Timing

Ah, the classic “I’ll just slap it on today” blunder. It’s 90 degrees out, or rain’s looming, and you dive in anyway. Epoxy hates extremes. I’ve seen pours in a steamy workshop bubble like soda, or in chilly garages, cure uneven and crack.

What’s Going Wrong

Humidity above 85%? Moisture gets trapped, leading to white haze or delamination. Temps below 50°F slow curing, leaving a weak bond. Industry stats peg weather-related fails at 25% of calls to coating services.

Smart Moves to Make

Aim for 60-80°F and under 60% humidity. Check the forecast—give yourself a 24-hour window. In a basement, crank a dehumidifier. For outdoor parking lots, early morning’s your friend; the sun’s not baking yet.

Picture this: A client in the Midwest waited out a heatwave for their commercial floor. Result? A seamless glossy shine that handles spills from day one, no fisheyes from sweat.

Mistake #4: Going Thin on Coats

One and done? That’s a rookie move. A single skimpy layer might look okay at first, but give it a forklift or chemical spill, and it’ll wear through quick. Warehouses I’ve toured show thin apps cracking under pallets in under a year.

The Downside

Epoxy builds thickness for strength—aim for 10-20 mils per coat. Skimp, and you lose that oil-resistant barrier, plus the wear protection. In corrosive spots like workshops, it means pitting and early replacement.

Layer It Right

Two coats minimum: Prime first for adhesion, then a full topcoat. Use a roller for even spread—about 200-300 square feet per gallon. Let the first cure 12-24 hours before the second. Glossy finish bonus: It hides minor imperfections while popping that clean look.

Fun fact—or not so fun: I once watched a crew overload the first coat, thinking it’d save time. Bubbles everywhere. Lesson learned the hard way.

Mistake #5: Rushing the Cure

The floor’s dry to the touch? Great, but don’t park the truck yet. Epoxy needs time to harden fully—48 hours minimum for light use, a week for heavy. Jumping the gun leads to dents, scratches, or that embarrassing tire mark story.

Why Patience Pays

Full cure builds the chemical resistance and hardness. Rush it, and oils seep in, softening the surface. For basements with moisture issues, incomplete curing amplifies mold risks.

Your Cure Checklist

Block off the area. Ventilate to speed things along without dust. Test hardness with a coin scratch after 72 hours. In logistics centers, schedule around downtime—better a delayed project than a redo.

One more thing: Ever smell that fresh epoxy whiff? It’s potent, so mask up. Your lungs will thank you.

Quick Comparison: DIY vs. Pro Application Pitfalls

To wrap these up visually, here’s a table breaking down how these mistakes hit harder for DIYers versus pros. It’s eye-opening.

| Mistake | DIY Impact | Pro Impact | Quick Fix Tip |

| Surface Prep | High—tools are pricey to rent | Medium—routine but rushed sometimes | Etch and degrease in one pass |

| Mixing Ratios | Very High—easy to eyeball | Low—calibrated equipment | Weigh it out, no guesses |

| Weather/Timing | High—home schedules ignore forecasts | Medium—jobs get postponed | Check apps like Weather Underground |

| Thin Coats | High—runs out mid-job | Low—bulk supplies | Buy 20% extra for safety |

| Rushing Cure | Very High—eager to use space | Low—client contracts enforce waits | Post signs: “Wet Floor—Wait!” |

See? Pros aren’t immune, but prep changes everything.

Spotlight on Konaz: Your Go-To for Epoxy Floor Coatings

If you’re hunting for a reliable source to nail your next project, look no further than Konaz. Based out of Foshan, we’ve been knee-deep in functional coatings for over 15 years, cranking out top-shelf stuff from our 3,000-square-meter setup. Our epoxy floor paints? They’re built tough: sky-high hardness to laugh off scuffs, bulletproof against oils, chemicals, and rust, with that smooth glossy vibe that makes spaces feel pro. Slap ’em on easy—roller, spray, whatever—and watch ’em last with next to no fuss.

We cater to the real world: gritty workshops, sun-baked parking lots, buzzing warehouses, leaky basements, you name it. Annual output hits 1,000 tons, so we’re not messing around. Folks from automotive shops to logistics hubs grab our kits because they deliver— no peeling, no yellowing, just solid performance. Swing by konaz.cn to check specs or chat with our team. We’re all about making your floor game stronger, one coat at a time.

Wrapping It Up: Get Your Epoxy Right the First Time

There you have it—the big no-nos that turn a solid epoxy job into a regret. From skimping on prep to ignoring that cure clock, these slips are sneaky but beatable. Nail the basics, and you’ll land a floor that’s not just pretty but punishingly durable. Think about your space: That workshop seeing daily spills? The parking lot battling salt in winter? Epoxy, done smart, handles it all.

Bottom line: Invest the time upfront. It’s cheaper than ripping it out later. Grab a kit from a trusted spot like Konaz, follow these pointers, and you’ll be the one giving advice down the line. Your floors—and your sanity—deserve it.

Frequently Asked Questions About Common Mistakes to Avoid When Using Epoxy Floor Coatings

What’s the biggest common mistake to avoid when using epoxy floor coatings in a busy warehouse?

Hands down, it’s rushing surface prep. Dust or oil left behind means poor adhesion, and in a warehouse with forklifts zipping around, that leads to quick peeling. Grind it clean, degrease thoroughly, and you’re golden—our coatings bond like they should.

How do I steer clear of mixing errors as a first-timer with epoxy floor coatings?

Stick to exact ratios; don’t wing it. Use a scale for the resin and hardener—most need 2:1. Stir slow to kill bubbles. I’ve seen too many tacky floors from sloppy mixes, but get this right, and you’ll hit that hard, glossy finish without issues.

Can weather really tank my epoxy floor coating project?

Absolutely—one of the top common mistakes to avoid when using epoxy floor coatings. High humidity traps moisture, causing haze; cold snaps slow curing. Shoot for 60-80°F and dry air. In a basement? Dehumidify first. It makes all the difference for longevity.

Why do thin coats cause so many headaches with epoxy floor coatings?

They just don’t build enough thickness for protection. A single skimpy layer wears fast under traffic, losing that oil and chemical resistance. Go two coats, 10-20 mils each, for the full wear-resistant punch. Pros swear by it for spots like parking lots.

How long should I really wait before walking on fresh epoxy floor coatings?

Don’t rush—48 hours for light steps, a full week for heavy use. It’s a common mistake to avoid when using epoxy floor coatings that leads to dents. Block it off, ventilate, and test for hardness. Patience gets you that low-maintenance shine that lasts.