Walk into a gas turbine hall during a hot summer peak-load afternoon, and you’ll instantly understand why surface protection matters. The air feels heavy. The turbine casing radiates heat even from several feet away. Inside the machine, temperatures spike far beyond what most industrial metals can comfortably tolerate. Blades, vanes, combustor liners, transition pieces—every one of them is working at the edge of its thermal limit.

Gas turbines in combined cycle power plants are efficient, powerful, and incredibly demanding on materials. They run hotter than almost any other equipment in a thermal power facility, and operators push them hard because higher firing temperatures mean better fuel efficiency. But the downside is obvious: extreme heat accelerates oxidation, scaling, surface fatigue, and coating failure.

This is where heat resistant coatings, especially those designed for metal substrates exposed to violent thermal shock, come into play. They don’t magically drop the firing temperature, but they do change how the surface reacts to those temperatures—and that difference often translates into longer part life, fewer unexpected shutdowns, and a smoother operating cycle.

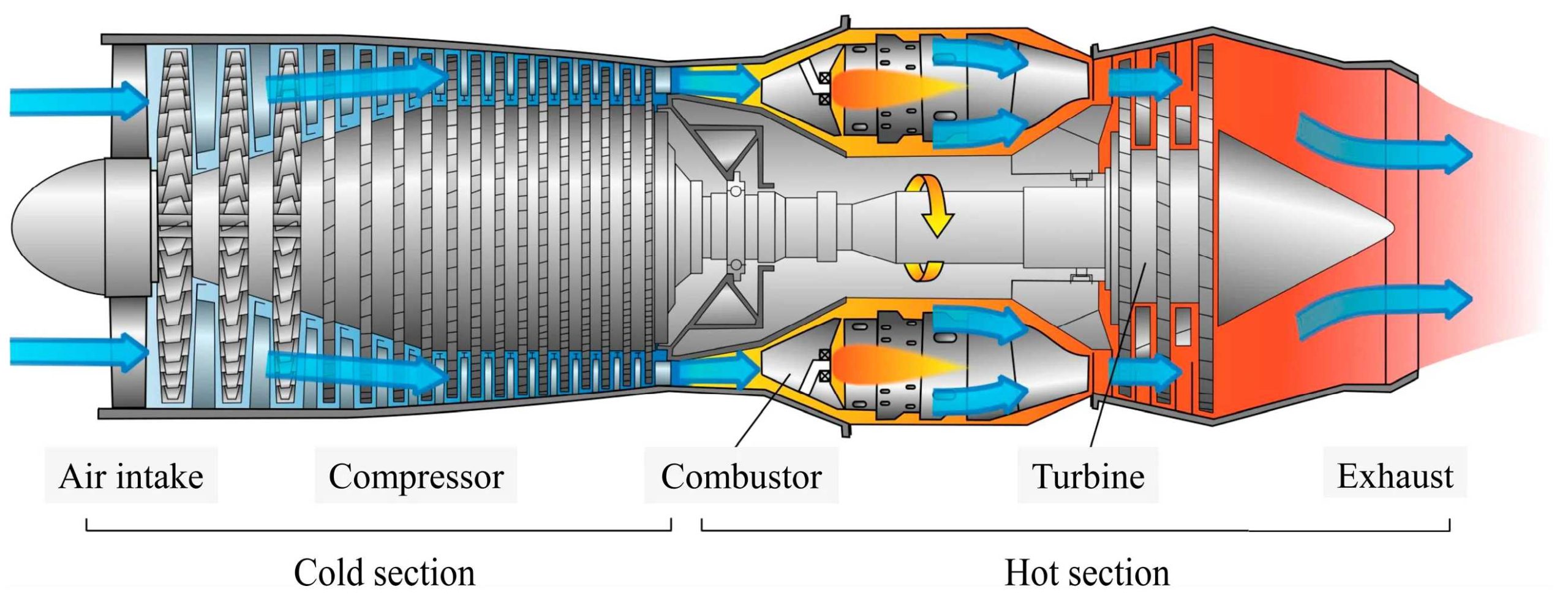

Why Gas Turbines in Combined Cycle Plants Stress Components So Severely

Combined cycle (CCPP) designs aim for maximum thermal efficiency. Gas turbines run at high firing temperatures to achieve better heat rates, and the exhaust gas is then used to produce steam in the HRSG. The problem? Those firing temperatures have been creeping up year by year.

It doesn’t matter whether the turbine is new or has been in service for a decade—at 1,200°C or more, the environment inside a combustor or turbine stage is unforgiving.

Let’s break down the main sources of damage.

Extreme Oxidation at High Temperature

Once metal surfaces reach certain temperature thresholds, oxidation doesn’t just increase—it accelerates almost exponentially.

Blades and vanes in the hot section face:

- High-velocity gas streams

- Oxygen-rich combustion zones

- Repeated exposure to hot spots

- Trace contaminants like sulfur or vanadium

Bare metal stands little chance of surviving long under these conditions. Even alloys designed for turbine use will erode and oxidize faster than expected if left unprotected.

Thermal Shock and Rapid Cycling

Gas turbines rarely stay at one temperature for long. Daily starts and stops, fast load changes, and frequent cycling in power markets create harsh temperature transitions.

Imagine a blade surface jumping from cold iron to searing combustion temperatures in minutes—that level of expansion and contraction creates stress:

- Micro-cracks

- Spalling

- Localized fatigue

- Erosion from thermal mismatch

Once cracks start, they tend to spread fast.

Deposits, Scaling, and Hot Gas Corrosion

Contaminants in the fuel or intake air can combine with high heat to form aggressive deposits on turbine surfaces. Scaling not only insulates the surface—raising the metal temperature underneath—but also contributes to structural deterioration.

The result?

Higher heat, faster aging, and increased maintenance intervals.

How Heat Resistant Coatings Protect Turbine Components

Heat resistant coatings used in gas turbines don’t rely on a single trick. Instead, they provide a stack of protective benefits that collectively slow down the deterioration process.

Based on the product performance information you shared, coatings with the qualities similar to those produced by Foshan Konaz Technology Co., Ltd. tend to provide these advantages:

Barrier Protection Against Oxidation

A heat resistant coating forms a physical and chemical shield between hot gases and metal surfaces. This slows oxidation and reduces metal loss over time. A stable coating film also prevents oxygen from penetrating deep into the microstructure of the metal.

Strong Adhesion That Survives Thermal Cycling

Not every coating can handle expansion and contraction without cracking. Thick coatings often fail first. What’s needed is a thin, tightly bonded film that flexes with the metal instead of resisting it.

The durable adhesion and non-peeling performance described in your technical documents align well with this requirement.

Reduced Scaling and Deposit Buildup

A smooth, stable coating surface makes it harder for contaminants to stick. This means:

- Less insulating residue

- Lower metal temperatures

- Fewer hot spots

- More consistent turbine efficiency

This may sound subtle, but tiny improvements in surface cleanliness add up quickly in long-term turbine operation.

Protection During High-Velocity Particle Impact

Turbine components face constant sand-blasting from particles carried by the gas stream. A resilient coating absorbs some of that punishment instead of the substrate metal taking the hit.

Aesthetic Stability That Helps With Inspection

While color stability at high temperature might sound cosmetic, in practice it matters during inspections. When a coating doesn’t discolor even near 800°C or more, operators can spot real damage instead of mistaking color changes for cracks.

Where Heat Resistant Coatings Are Most Effective in a Gas Turbine

Heat resistant coatings are especially valuable in the hot section where temperatures and velocity are at their peak.

Combustor Liners

The inside of a combustor is one of the harshest environments in the plant. Coatings help reduce oxidation and cracking in this zone.

Transition Pieces

These components handle both thermal shock and turbulent flow. A stable coating adds extra buffer against rapid temperature swings.

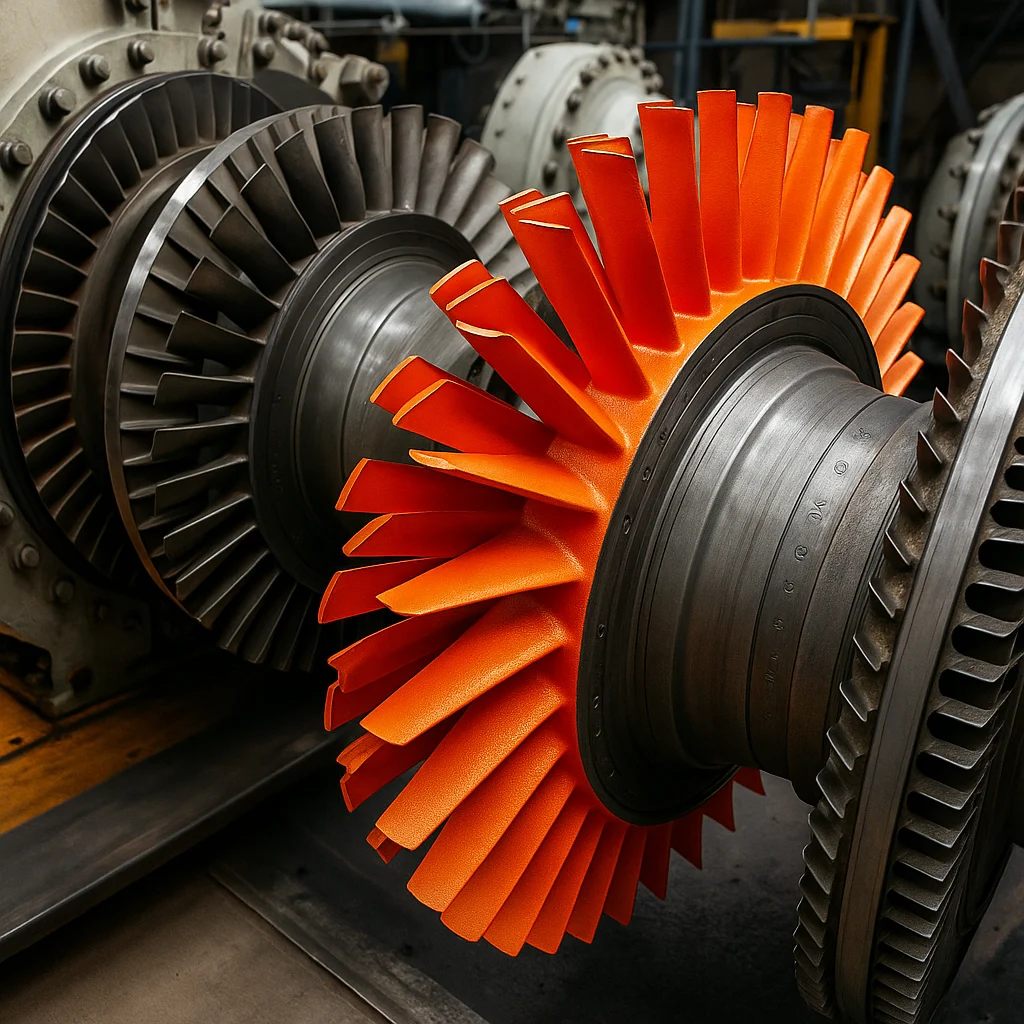

First and Second Stage Blades / Vanes

These airfoils face the highest thermal and aerodynamic loading. Even a small reduction in surface oxidation can dramatically improve fatigue life.

Exhaust Components

Even though temperatures drop here, long-term corrosion and scaling are still concerns, especially when fuels vary.

Why Combined Cycle Plants Benefit More Than Simple Cycle Units

CCPP turbines often see daily cycling because they serve intermediate or mid-merit loads. This means hot starts, warm restarts, and shutdowns are routine. Each cycle stresses turbine metals.

Heat resistant coatings help in several ways:

- They delay crack initiation

- They reduce metal temperature rise during hot spots

- They keep surfaces clean, improving steam production efficiency

- They stabilize heat flow into the HRSG

In short, coatings support overall plant efficiency, not just turbine longevity.

About Foshan Konaz Technology Co., Ltd.

Foshan Konaz Technology Co., Ltd. has spent the past 15 years developing coating materials that survive extreme thermal environments. The company’s high-temperature coatings—based on the technical features described in the document—are crafted around practical industry needs:

- No discoloration even under direct 800°C flame

- No peeling or film failure during thermal expansion

- Strong adhesion on metal substrates that experience rapid temperature changes

- Long-term resistance to oxidation and corrosive flue gases

The company operates a 3000㎡ facility with advanced production equipment, supplying coatings used on metal components exposed to severe heat, from industrial furnaces to automotive exhaust systems.

While not originally focused on gas turbines, the performance characteristics align well with the demands of turbine hot-section surfaces in combined cycle plants.

Conclusion

Keeping a gas turbine in good shape isn’t about fighting fires—it’s about slowing the tiny, invisible failures that accumulate over every hour of operation. Oxidation, scaling, thermal shock, and surface cracking don’t happen suddenly. They creep in little by little until a blade inspection reveals something no one wants to see.

Heat resistant coatings give operators a way to push back. They don’t replace cooling systems or alloy design, but they add a layer of stability in a place where even small improvements matter. For combined cycle plants juggling frequent starts and stops, coatings can mean smoother operation, more consistent heat rates, and fewer unplanned outages.

Coatings built with the durability and temperature stability seen in Konaz’s product line provide a solid foundation for long-term turbine protection—especially in the hottest, most punishing sections of the machine.

FAQs

Why are heat resistant coatings important for gas turbine components?

Because turbine metals face extreme heat and fast temperature swings. A good heat resistant coating slows oxidation, reduces scaling, and helps prevent thermal fatigue cracks.

Do heat resistant coatings actually improve turbine efficiency?

Indirectly, yes. Cleaner surfaces transfer heat more evenly, and reduced scaling helps maintain stable combustion and smoother airflow. Over time, this contributes to better operating efficiency.

Which turbine parts benefit the most from heat resistant coatings?

Combustor liners, transition pieces, and first-stage blades see the biggest gains because they face the highest temperatures and gas velocities.

Can coatings survive repeated start-stop cycles in combined cycle plants?

Coatings with strong adhesion and non-peeling characteristics—like the ones described in Konaz’s technical documentation—are built to tolerate frequent thermal cycling.

Are these coatings only used in turbines?

No. Similar coatings are widely used on industrial furnaces, high-temperature pipes, automotive exhaust systems, and other metal surfaces exposed to intense heat.